In today’s increasingly airtight buildings, balanced heat recovery ventilation sytems are essential for achieving healthy, dry and energy efficient indoor environments.

What is Heat Recovery Ventilation?

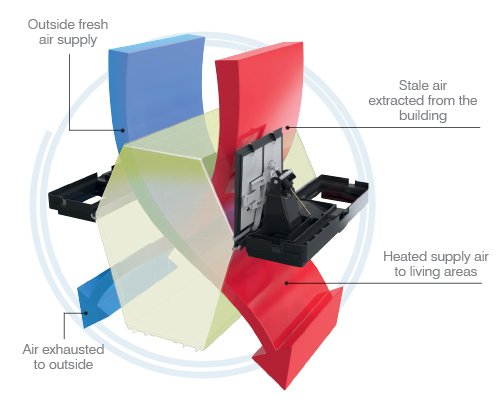

Heat Recovery Ventilation Sytems or Mechanical Ventilation Systems with Heat Recovery (MVHR) provide fresh air to each living space within a building and remove warm, damp air from wet space like kitchens or bathrooms.

By passing the outgoing warm stale air through a heat recovery core, up to 90% of the energy can be recovered and passed to the incoming fresh air. This results in drastically reduced winter heating bills and healthy dry air.

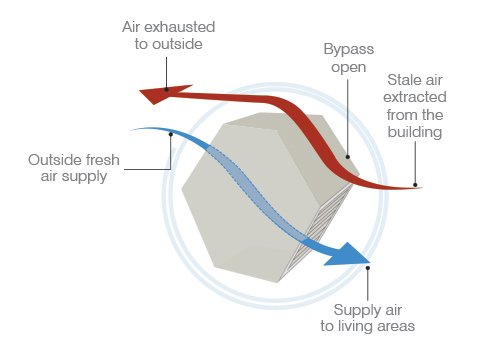

During the summer months, the computer controller within the unit is able to either cool incoming warm air using the out-going cool air, or switch to ‘bypass mode’ where warm air from within the home is dumped outside without recovering the heat.

Zehnder Comfoair Q350 ventilation system

Heat Recovery Core - Winter

Heat Recovery Core - Summer Bypass

Design Consultancy Services

Proper design of heat recovery ventilation systems is essential to their success and affordability. A poorly designed system can lead to significant extra expenses on site, poor performance, noise, and in some cases unit failure.

High performance building services has years of experience designing, installing and maintaining Zehnder systems and we understand what is required to allow these systems to perform at their best.

Talk to us early in your design process to ensure the best possible performance of your system.

Supply & Installation

High Performance Building Services are specialist suppliers and installers of the Zehnder Comfoair range of heat recovery ventilation systems within the Dunedin area.

Zehnder heat recovery ventilation systems are widely recognised as one of the best domestic heat recovery ventilation systems on the New Zealand market, with industry leading heat recovery (85-90%) and high quality European design & construction.

Commissioning

Commissioning is the final essential step to ensure that the ventilation system performs as designed.

Commissioning is the process of adjusting fan speed on the MVHR unit and altering the flow rates through the air valve in each space. The objective is to deliver the right amount air to habitable spaces, while extracting an equal volume of air from the wet spaces.

When you get the combination right, you get the best possible level of airflow, with the least noise and the greatest efficiency.

The air flow through each valve is measured using a an anemometer and the values are adjusted and then recorded on the commissioning sheet which is then provided to the consenting authority or in some cases the Passive House certifier.

If the system is set too high it can create noise. The goal is to run the unit as slowly as possible to reduce noise, cut vibration and exchange the right amount of air over the desired timescale. The lower the running speed, the more energy efficient, cost effective and long-lasting the system will be.

A few of our projects

Support & Maintenance

-

Filter replacement & valve clean

Zehnder recommend 6 monthly replacement of unit filters, return filters and and cleaning of valves. Replacement filters are available from our website

-

Servicing & Duct Cleaning

Zehnder recommend 4 yearly servicing of the system by a professional including duct cleaning and cleaning the heat exchange core.

-

Bearing or sensor replacement

Replacement of Zehnder bearings and senors

Book a service

To book your ventilation service and for more information, leave us with your details and we'll be in contact to discuss further options.